The key to understanding and optimising your engineering projects

Central to all of our work is the development and creation of high quality, accurate 3D models. From this starting point we can move to generating overall scenes combining vessels, platforms, subsea arrangements and everything in between.

By building these 3D scenes we can then introduce motion, which is where the advantages of animated assets interacting with each other become clear, providing you with the best view possible.

High poly and low poly modelling

There are many ways to approach modelling assets, but in general they can be divided into two main methods, being high poly modelling and low poly modelling. High poly modelling is often used for items that are the focus and therefore demand greater detail, making use of sub-division surface techniques. Low poly modelling can be used for less prominent items or features and utilises smoothing group settings and photographs to help indicate the detail where needed. Both general methods can be used across all projects depending on the requirements of the primary and secondary items in the scene. We can select the most appropriate techniques to best match your project goals and deadlines.

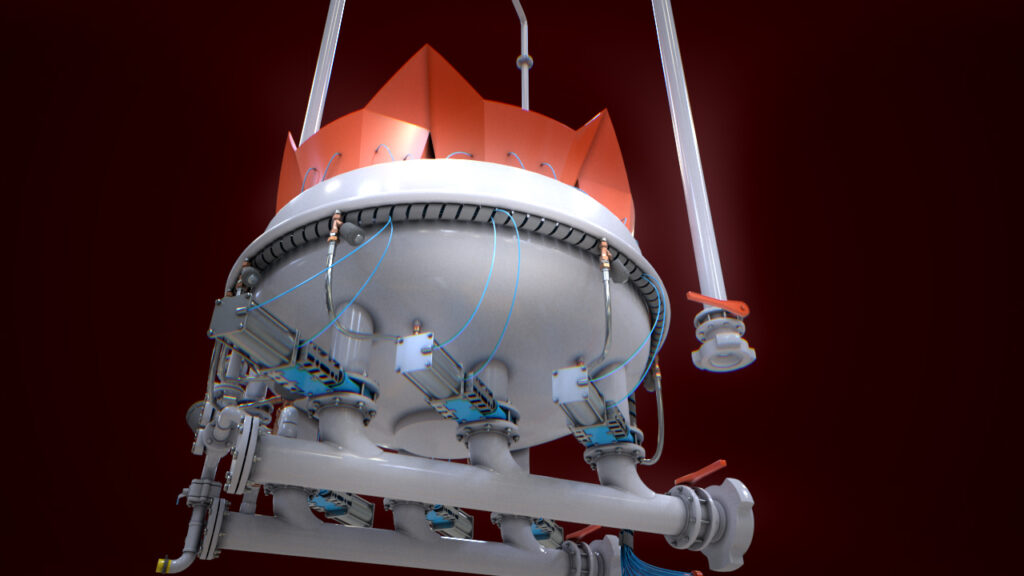

Rigging arrangements

Complicated rigging arrangements involving cranes, winches and taglines are examples of how valuable 3D modelling can be in visualising set ups for both surface and subsea interactions. Whether it’s detailing rigging lengths or angles, via technical animation we can demonstrate how rigging arrangements will look and react, making use of scratch-modelled items as well as those imported from available libraries and supplier catalogues.

Assembly procedures

When communicating how things should go together or how they should be fitted into position during meetings with clients or technicians at the worksite it can be hugely advantageous to have an assembly procedure in video format. This means that the video can be viewed with all interested parties, improving understanding and acting as training for specific tasks “on the job”. These sequences can also help with confirming the order in which parts should go together, how they will interact while being fitted or removed, and highlight any potential issues with clashes and reduce the risk of mistakes being made during installation.

Concept design and virtual prototyping

When a fast-turnaround design is required and where only simple sketches and details are available, 3ds Max is the ideal software to quickly develop your concept through to a presentation stage. This means you can get your idea digitally mocked-up in three dimensions such that views and animations can be produced, with general dimensions and details added to best communicate the concept. 3D models can be created based on hand-drawn sketches and GA-type drawings, helping you to visualise and progress your design.