Understand what will happen and how to improve it

Offshore operations present us with some challenging animation tasks, from handling flexible products often with complicated lifting arrangements, to large structures being deployed to the seabed or between floating assets. In all cases, project efficiency can be improved by making use of fully featured 3D models, scenes and animations. What can now be achieved in the virtual space in terms of design and engineering can greatly enhance project execution from concept through to live operations.

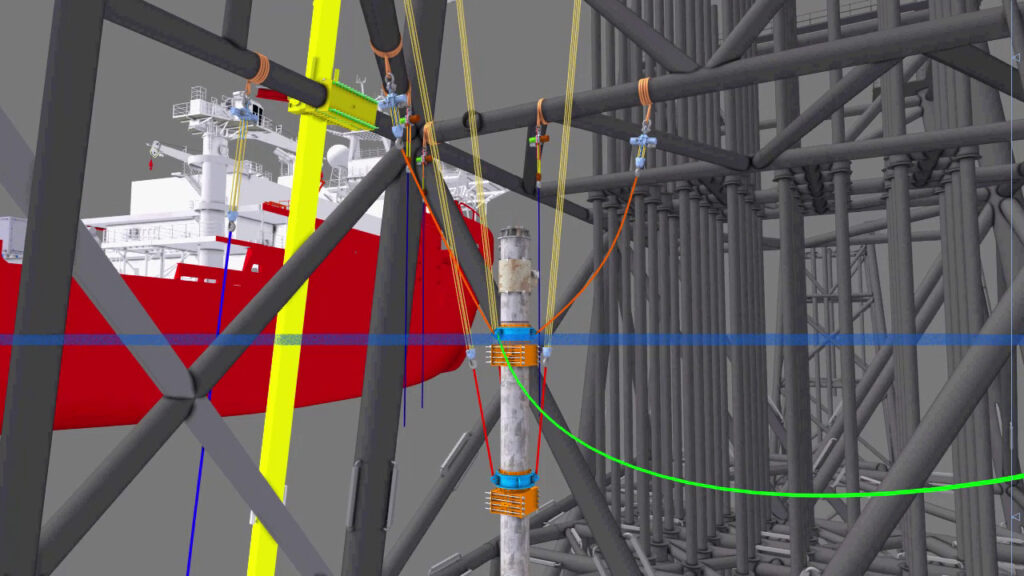

Crane lifts and clash checks

Checking for clashes is a key stage in planning any lift operation, and that process can only happen within a fully 3D modelled environment to ensure all elements are included and considered. Large structures, with many contact points in terms of rigging – crane, winches, tagging towers – are an excellent example of why both the vessel and crane should be modelled in 3D and combined with client-supplied CAD of the structures or other assets being lifted. With these various items in place, it is possible to check clashes and rigging lengths which aid creating procedure documents and help detail the various stages of the lift.

Animated procedures

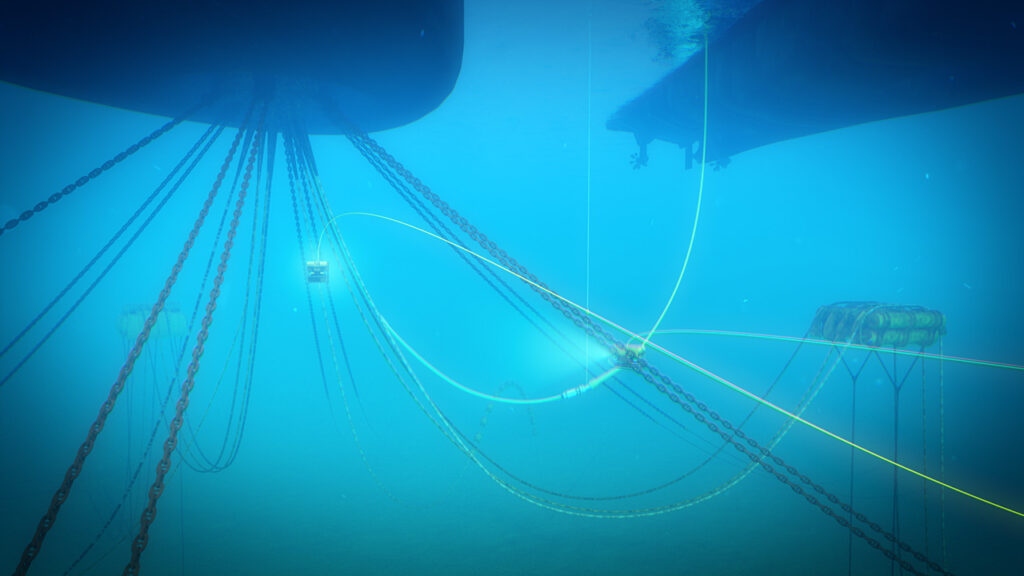

Umbilicals, flexible jumpers and risers offer challenges when it comes to offshore deployments, whether it be from vertical lay systems or over-the-side chutes. Rigid pipelines, either deployed from a ramp or stinger, also require various interactions with cranes, winches and tensioners. Subsea structures, caissons, topside modules and bespoke tools require multiple interactions with lifting gear, hoists, winches and cranes. In all cases there are various stages of deck ops to plan as well as winch and lifting sequences. That’s where having a 3D animated arrangement is key, and why developing the deployment or recovery procedure in 3D can both reveal issues before they become problems and demonstrate opportunities for better methods.

Line of sight illustrations

From pulling or holding back flexible products, to subsea lifting operations routed through sheaves and fairleads, winch lines are best planned utilising 3D layouts and supporting models. That way all potential clashes and interactions can be highlighted and worked around. We can develop views showing fleeting angles, help with optimising winch locations and demonstrate proposed operations in appropriate levels of detail. Planning how the winches are connected and disconnected is a large part of establishing a successful procedure, with details on length of wire, wraps on the drum and spooling positions all available through 3D modelling.

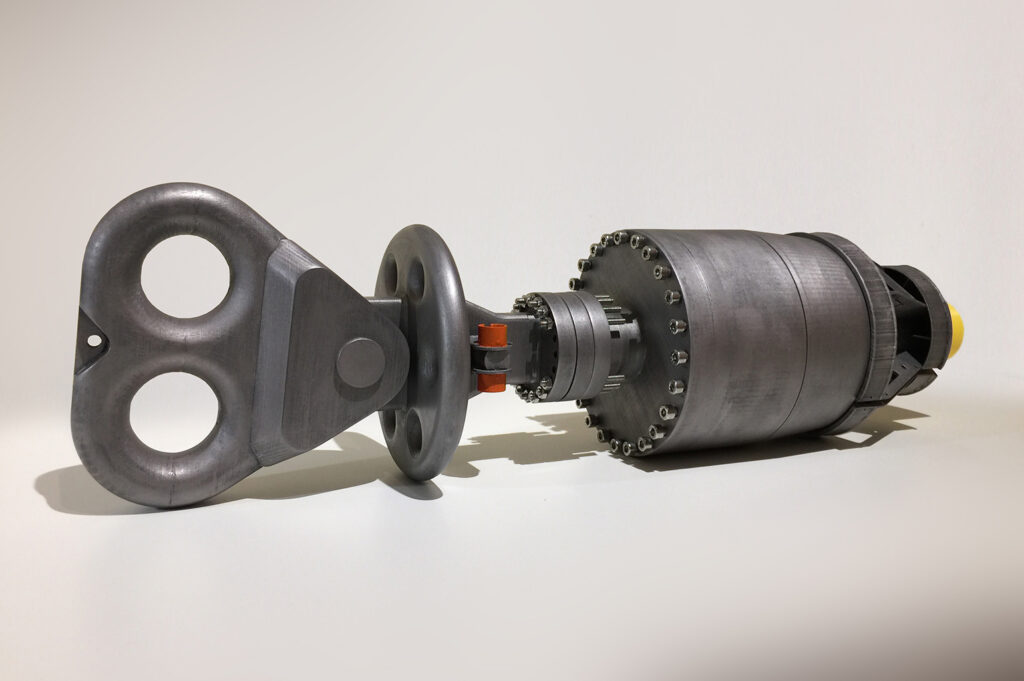

3D printing and model making

Physical models are an excellent way of representing your products for use in meetings and presentations, highlighting full-sized rigging items through to scaled structures. We can make use of FDM and SLA printers to best match your product requirements, with models delivered with appropriate finishes and branding.