eCSOV stands for “electric Commissioning Service Operation Vessel” and it is a zero-emission vessel (a worlds first for the industry) that will serve offshore wind farms. The purpose of the visualisation work was to showcase the vessel, a new build coming from Bibby Marine, and present it in-situ both inside and out allowing for the main features to be highlighted. This involved modelling the vessel from general arrangement drawings, working through paint schemes for the hull, developing interior spaces and generating a variety of promotional images. The main focus of the project was to create a high-quality animation to be used in marketing, presentations and industry events.

Getting started

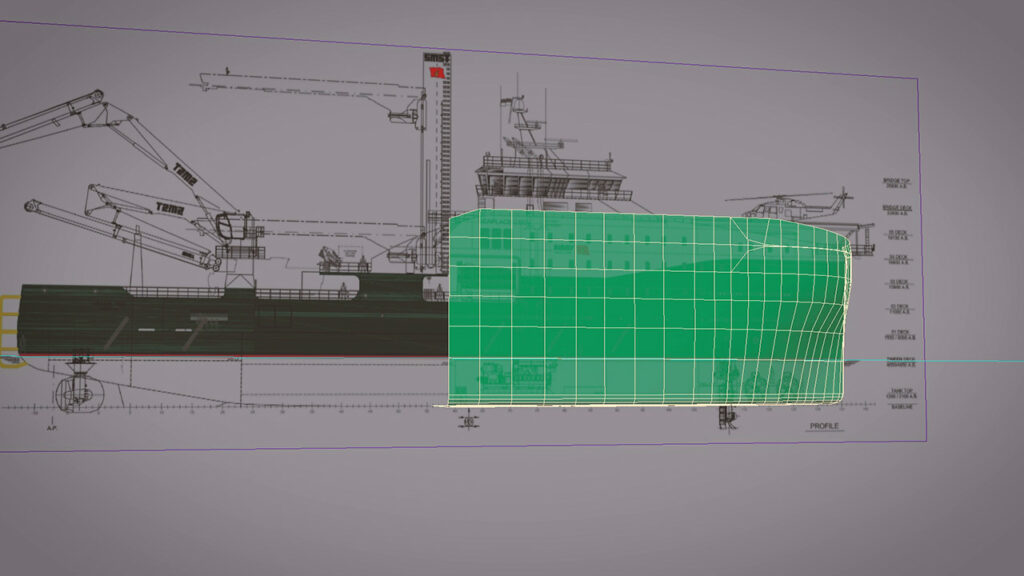

The source material for building the vessel model was a standard GA drawing, including an elevation, cross section and the various deck plans. As it happened, the GA was in a bitmap format, meaning there were no splines or vectors depicting the technical drawings so instead ‘images’ of the orthographic views were captured and brought into Autodesk 3ds Max for alignment and scaling. As always, the drawings are set up at full scale, 1:1 meaning that the resultant model is compatible with all other scenes and general models in our library.

The only advice on this sort of bitmap based setup is to ensure the background colour of the drawings is set to something other than white (such that construction lines stand out clearly when producing splines and geometry in 3ds Max).

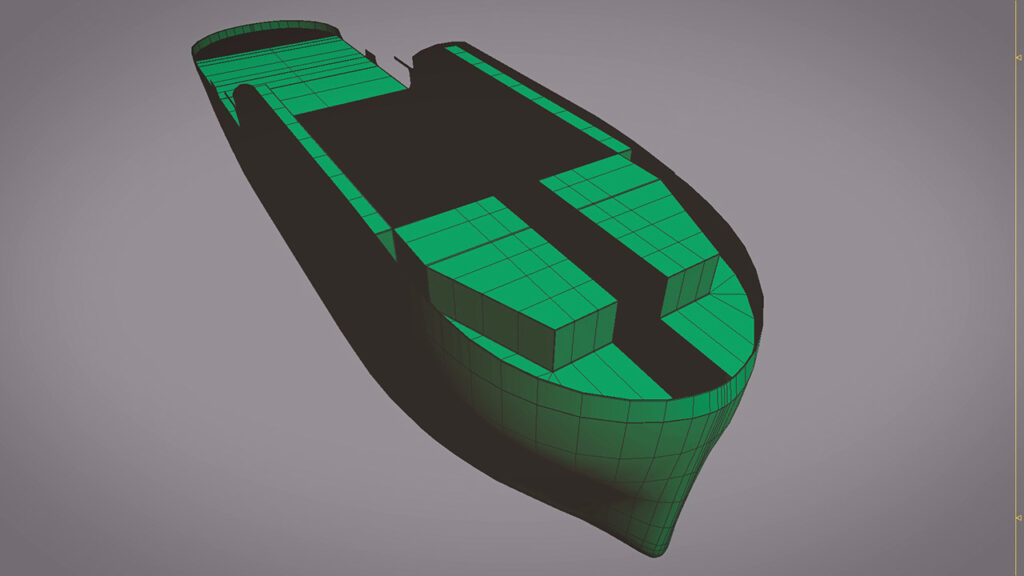

From here, the model is initially blocked out in broad steps to form out the overall shape of the hull. The aim being to generate a ‘watertight’ mesh that can be further worked with detail added over the coming steps. In the early stages, symmetry can be utilised to help get the main forms created quicker, but as with most vessels there are differences between the port and starboard.

Building up the detail

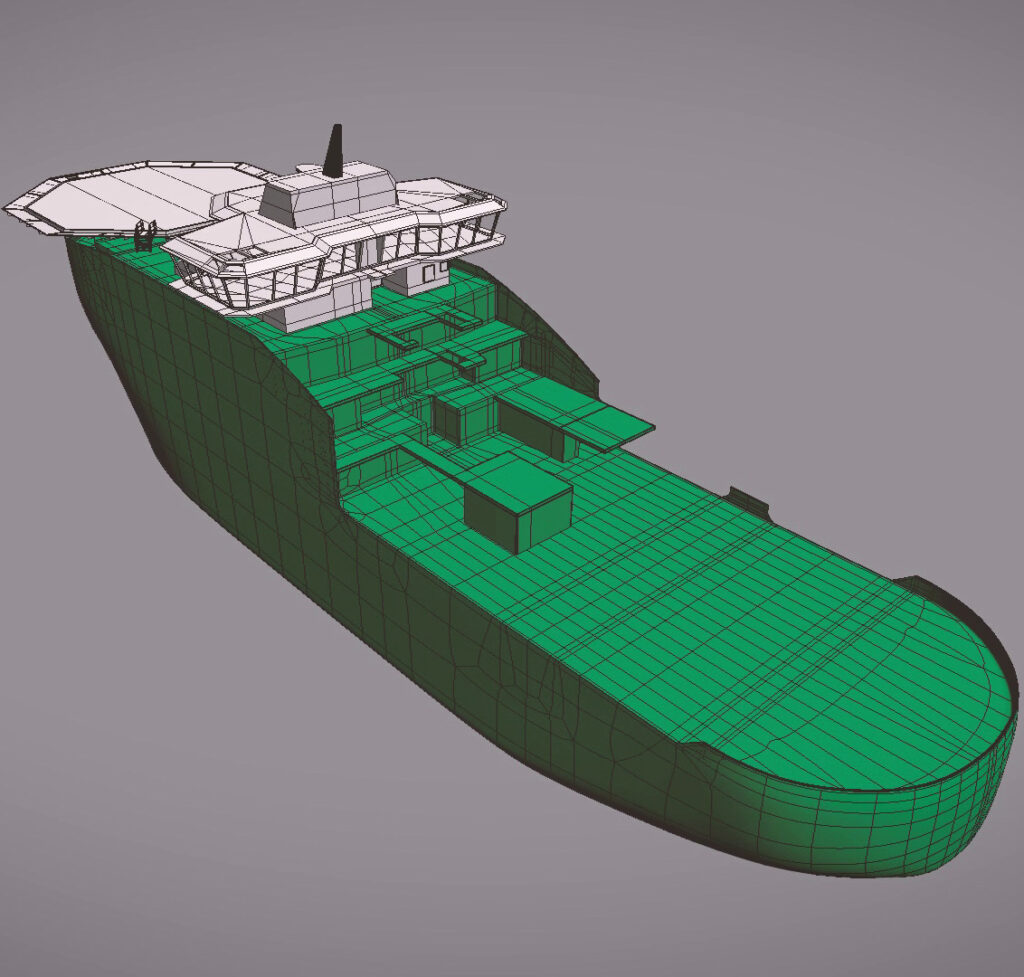

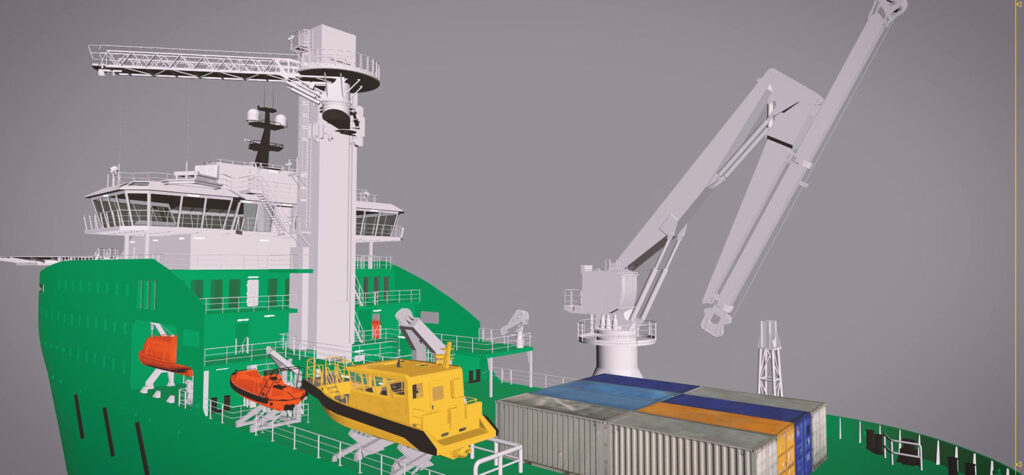

With the overall form created, the work then turns towards increasing the detail, either by cutting in new shapes to the hull mesh itself or by adding elements separately to keep things clean (in terms of the underlying topology). Railings, stairs and barriers are a great way of adding detail in a straightforward process with the use of lines tracing along the guides in the CAD drawings, then using extrusions and renderable splines.

Windows and doors are achieved either by surface detailing on the hull or by cutting in holes through to internal spaces. Windows, frames and seals can then be indicated by extracting splines from the cavities. Various items around the main deck, such as capstans and piping, through to the additions up on the wheelhouse including the radar, exhausts, comms equipment and searchlights all enhance the quality of the result and are worth the time in modelling for the benefits they bring.

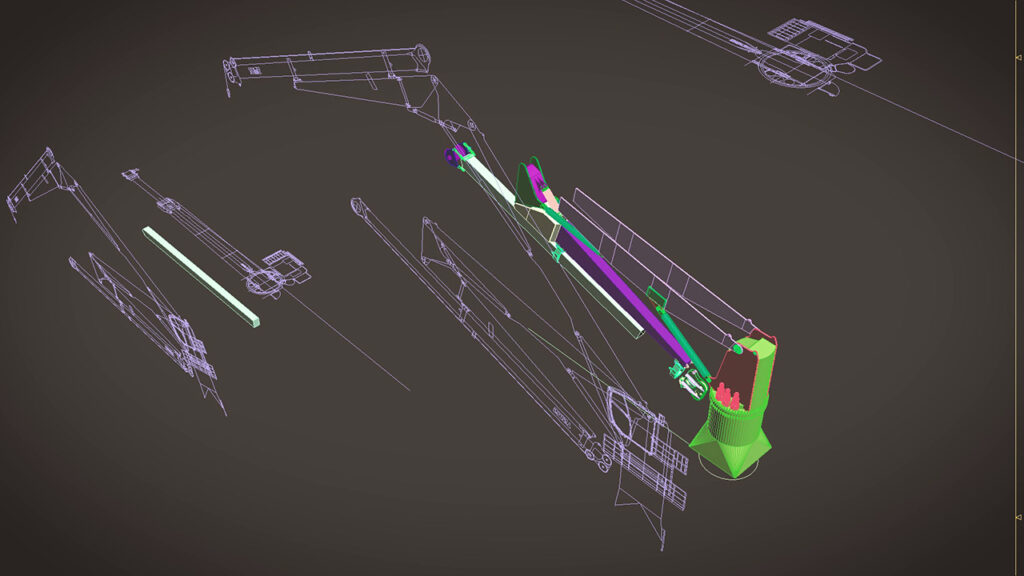

Key items on the main deck such as the crane and gangway are modelled from CAD drawings also, this time using source linework from AutoCAD.

The various elements of these are linked and rigged so that they can be posed and animated where needed. These are using constraints such as LookAt and Orientation for a simple but effective hierarchy.

Creating interior spaces

Linking the outside hull and structure with the interior spaces was important for providing a continuous fly-through of the vessel that allowed for the camera to move from the outside to the inside and back and forth. This would give the animation a unique and dynamic feel as it helped show the audience where the various spaces are in relation to the overall design which is often not the case in vessel visualisation. The norm is to show the locations separately with scene fades.

Floor plans from the deck drawings were used as a starting point to extrude walls and to then provide the structure for adding floors, ceilings and doors. Modelling the interior spaces like this meant that furniture and objects could be added along with people working in the spaces for context and to give the fly-through a ‘lived in’ feel. Direction from the Client in terms of mood boards helped form the look and feel of the rooms and their decoration and colour themes.

Building the vessel in this way means that further rooms and spaces can be added to the model if and when required to expand on the interiors covered, tied into the vessel overall for a better perspective.

Painting the hull

In this case, the model uses both standard UVW mapping plus some specific UVW unwrapping to handle the geometric design used across the bow of the hull. In all there are over 25 different materials created for the vessel to cover the various surfaces using straightforward VRay Materials.

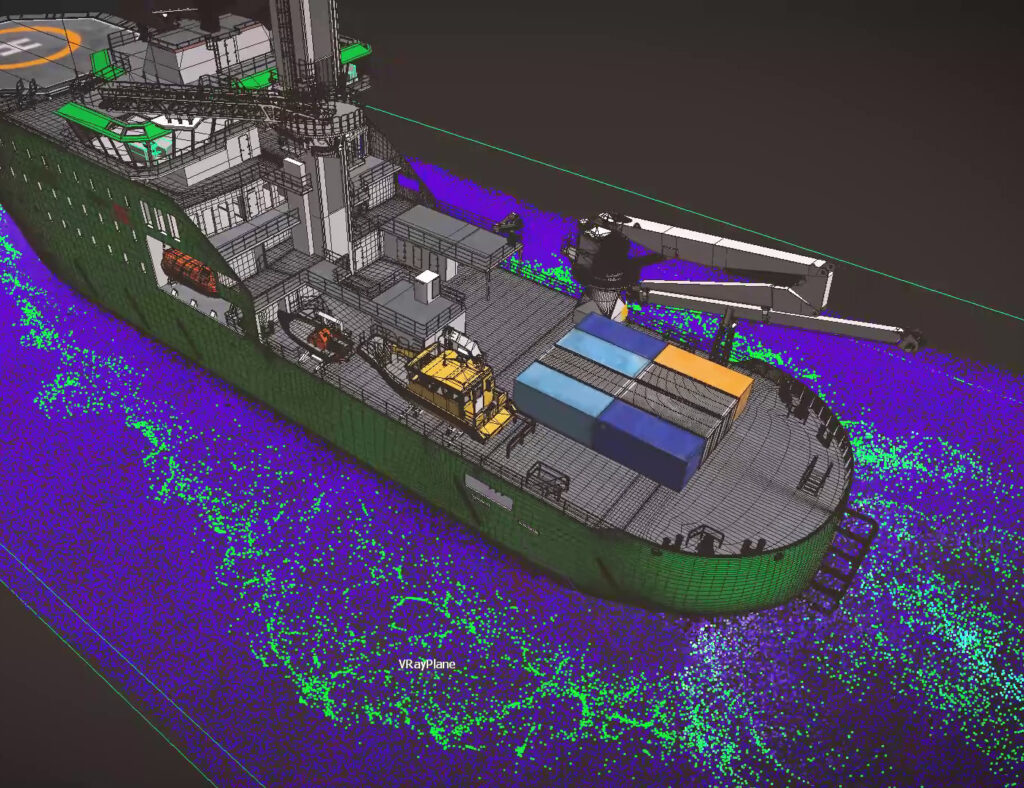

Liquid simulation

Where it added value, some time was spent setting up liquid simulations using Chaos Phoenix to help create the effect of the vessel sailing through the ocean producing wakes and foam.

Many gigabytes of data were produced, but with efficient use of the simulation tool the scenes were focused on the opening shots where the vessel was shown in transit to the wind farm.

Wind farm construction

A non-specific wind farm arrangement was assembled by first modelling a wind turbine and fixed foundation from CAD drawings. The overall scene was setup to help indicate an expansive field such that there were turbines in the background and surrounding the vessel when shown in animation, helping to explain how the vessel operates in-field and alongside the foundations for crew transfer ops. The efficiency here is that only one WTG is required that can then be duplicated across a wide array and the rotation timings on the blades varied.

Animation phase and results

The finished animation takes the form of a three-minute sequence with accompanying voice over, music and sound effects. This all helps turn the video into a standalone presentation piece that can be used in numerous situations. Generating an animation with this range of views and scenarios also has the benefit of providing plenty of still images that can be captured from the animation and used on marketing and websites. The Client, Bibby Marine, has since won the Next Generation Ship Award at Nor-Shipping 2025, and this work was used at the event (and in subsequent media posts and news stories).

It has been great to be involved in a future centric project like this, especially as an Aberdeen based 3D modelling and animation company where the offshore renewables industry is continuing to develop locally.

If you have a new (or existing) vessel that would benefit from being visualised this way, please use the Contact page to get in touch.